Carton Flow Racking

Carton Flow Racking

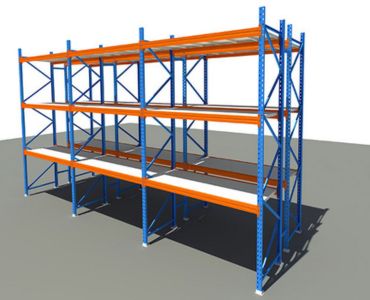

The Carton Flow Racking System (also known as the Gravity Flow Racking System) is a storage mechanism that uses the force of gravity to move boxes and cartons from the loading point to the picking end within a racking structure. This system comprises a chain of sloping shelves fitted with roller tracks, facilitating the smooth flow of cartons from loading to the picking end of the system.

This system is specifically designed to serve in environments where rapid and efficient order picking is a priority – making it an excellent fit for distribution centers and e-commerce warehouses. It is optimally used for storing and picking small to medium-sized items in large quantities, such as consumer products, automobile parts, and electronic devices.

The key advantage of the Carton Flow Racking System is its ability to boost productivity while minimizing the time and effort that goes into picking and restocking items. Furthermore, it provides easy access to stored items and ensures that the oldest products are picked first. This feature aids in curbing inventory wastage and spoilage, making this system cost-effective and efficient.

The carton flow racking system is highly versatile, offering tailored solutions to accommodate specific storage needs and requirements. This system supports a range of roller track systems and shelving configurations. There’s the added benefit of integration with other racking systems like pallet racking, which further boosts storage capacity and provides a more flexible storage setup.

In summary, the carton flow racking system is an optimal choice for those seeking to enhance storage capacity, boost order picking efficiency, and lower operational expenses. This system serves as a cost-efficient alternative to conventional storage strategies, and its customization features ensure it fits particular storage needs and demands.